LEAKWISE controllers offer reliable solutions for processing signals from our LEAKWISE ID-220 Series Sensors, providing a reliable hydrocarbon leak detection and monitoring system. From basic single-sensor support to multi-sensor installations, our controllers ensure correct sensor signal analysis and status reporting for various industrial applications involving oil usage.

LEAKWISE controllers are designed to meet diverse industry needs, offering robust performance in various environments. Available in weatherproof, explosion-proof, or without an enclosure, they are ideal for indoor, outdoor and hazardous locations.

Whether powered by AC, DC, or batteries, our controllers adapt to specific operational requirements, ensuring real-time access to critical spill detection and monitoring

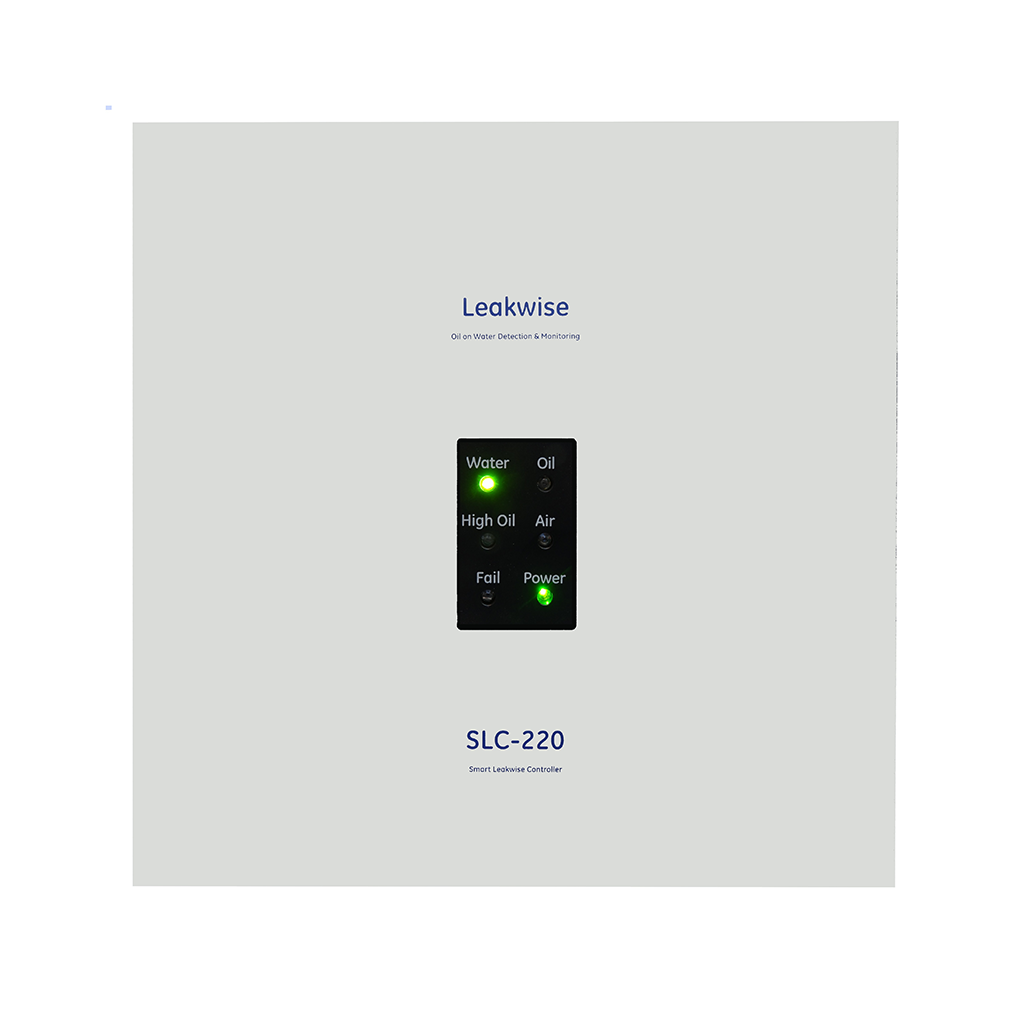

SLC-220/BASIC

Smart Leakwise Controller

SLC-220/MULTI

Smart Leakwise Controller

LEAKWISE controllers leverage the LEAKWISE sensors cutting-edge technology to deliver reliable system performance. They offer robust reporting options for local and remote monitoring, ensuring you have real-time access to critical spill detection information.

Above-Ground Oil Storage Tanks:

Early detection of spills and leaks due to overfill or roof drainage pipe failure, to prevent environmental contamination.

Transformer Sumps:

Monitoring oil leaks in switchyards and remote power distribution substations.

Oil / Water Separators:

Ensuring effective separation and early detection of oil at separator outlet due to excess oil volume at the inlet.

Cooling Water Systems and Trenches:

Detecting oil contamination in cooling systems.

Stormwater Run-Off:

Monitoring for hydrocarbons in stormwater collecting systems prior to release to treatment or to public water.

Wastewater Sewer Systems:

Ensuring compliance with discharge regulations and monitoring for treatment process upsets.

Retention Ponds and Canals:

Detecting and monitoring hydrocarbon leaks.

Boiler Condensate Tanks:

Monitoring for oil contamination in condensate tanks.

Groundwater Monitoring Wells:

Ensuring early detection of oil leaks from pipes and tanks to groundwater.

By choosing LEAKWISE controllers combined as a system with the appropriate LEAKWISE sensors, you are investing in technology that not only protects your operations but also contributes to a cleaner, safer environment.

LEAKWISE enables you to maintain compliance with environmental regulations and standards, providing peace of mind and operational assurance.