Home » All Products » Oil Sheen Sensor » ID-223/2000 Oil Sheen Sensor

LEAKWISE ID-223/2000 sensors excel in detecting thin layers of hydrocarbons on water surfaces in various environments prone to oil leaks, including both wet and dry sumps. These advanced sensors not only detect the presence of oil but also monitor its accumulation, providing valuable oil layer thickness trend data.

The sensor’s versatility extends to detecting and monitoring hydrocarbon leaks and spills in sumps, canals, and retention ponds. Furthermore, the ID-223/2000 plays a crucial role in monitoring wastewater treatment plant discharge, ensuring regulatory compliance and alerting plant operators to any disruptions in the treatment process.

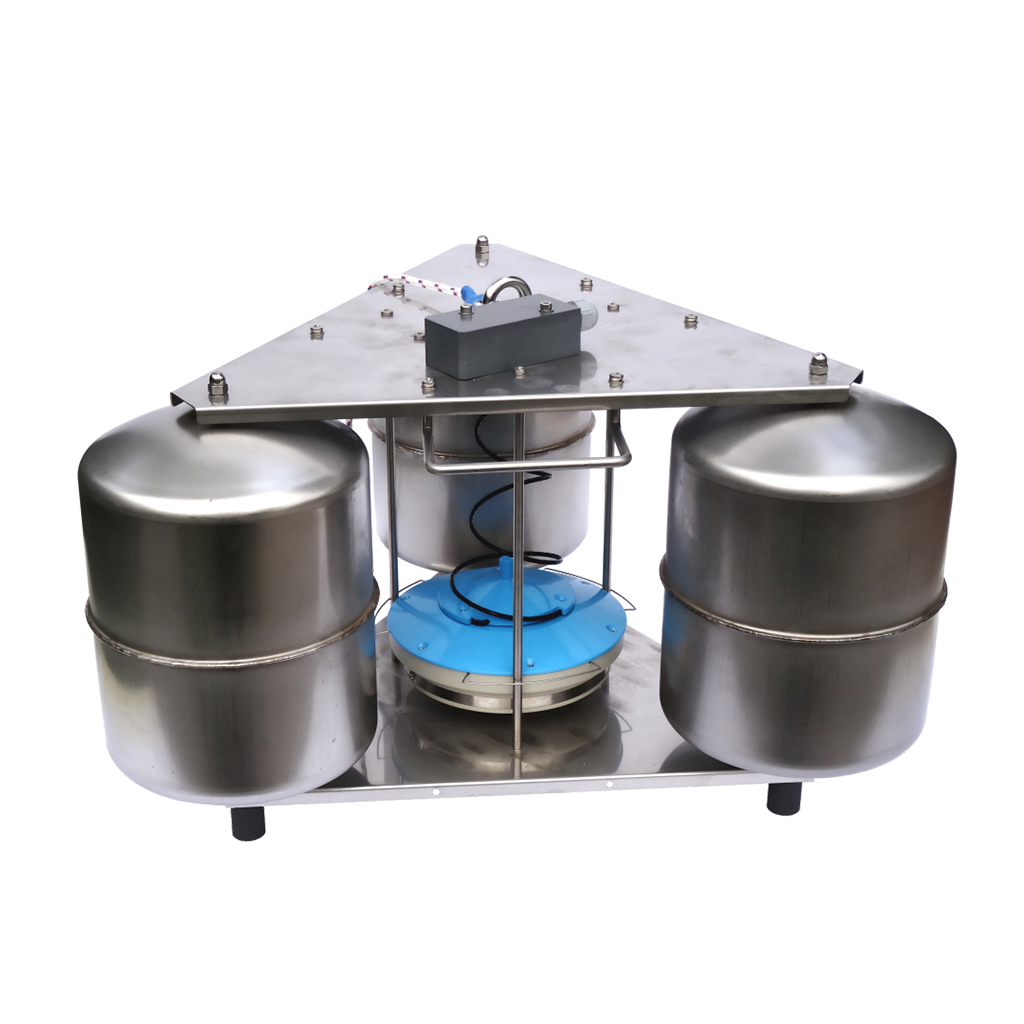

A LEAKWISE system comprises a controller and one or more sensors. The ID-223/2000 sensor features a high-frequency transmitter mounted on a float, built within a floating guiding cage. This design allows the sensor to maintain precise positioning at the liquid/air interface, even with liquid level fluctuations up to 2,000 mm (6.6 ft.) as standard, or up to 5,000 mm (16.4 ft.) on request.

The ID-223/2000 boasts exceptional sensitivity, capable of reliably detecting oil layers as thin as 0.3 mm (0.01 in) without false alarms. It continuously monitors changes in oil layer thickness up to 20 mm (0.8 in), transmitting this data via a 4-20 mA output signal from the controller. The system utilizes controller relays for both local and remote alarm and control functions. Built-in diagnostics continuously monitor sensor operation, ensuring reliable performance.

For more complex installations, the SLC-220 digital controller can manage up to four sensors simultaneously. To optimize performance in areas with high water flow or turbulence, a stilling tube is recommended for ID-223/2000 installations where lateral water velocity exceeds 30 cm/sec (11.8 in/sec). Integral stiller plates are available as an optional accessory.

The LEAKWISE ID-223/2000 is specifically designed for environments with maximum water fluctuations of up to 2,000 mm (6.6ft.) as standard, or up to 5,000 mm (16.4 ft.) on request, making it ideal for applications where large water level changes are expected.

ID-223/2000/MR is a sub-version of ID-223/2000. It has a floating cable and two mooring ropes. The ID-223/2000/MR is more suitable for ponds with a stable water level.

LEAKWISE ID-220 series sensors employ advanced high-frequency Electromagnetic Absorption technique. Each floating sensor contains high-frequency electromagnetic energy transmitting and receiving antennas that provide continuous monitoring of the liquid surface. This technology exploits the principle that water absorbs more electromagnetic energy than hydrocarbons.

Consequently, changes in the water’s absorption rate at the top layer indicate the presence or accumulation of hydrocarbons. LEAKWISE sensors are engineered to detect and monitor the buildup of both separated and emulsified non-soluble hydrocarbons on water and other aqueous solutions. A unique feature of these sensors is their ability to differentiate between wet and dry sump conditions, a capability unmatched by other oil sheen monitoring systems, allowing the indication of water level below the minimum required.

The ID-223/2000 Oil Sheen Sensor is a versatile and highly sensitive device designed for detecting and monitoring separated hydrocarbon layers on water surfaces, including in sumps that may be dry. This floating sensor is capable of detecting oil layers as thin as 0.3 mm and monitor oil thickness up to 20 mm. It operates effectively within a water level variation range of 70 – 2000 mm (2.8 – 78.7 in), adapting to large level fluctuations.

The ID-223/2000 is constructed with a 160 mm (6.3 in) diameter sensor made of hydrocarbon-resistant polymers and 316 stainless steel, ensuring durability in harsh environments. Its floating guiding cage has a diameter of 560 mm (22.1 in), allowing for stable operation. This robust design, coupled with continuous self-diagnostics, makes it a reliable solution for long-term hydrocarbon monitoring in various industrial applications, particularly where large water level changes are expected.

Detection Range: 0.3 – 20 mm (0.01 – 0.8 in) of separated hydrocarbon on water or brine

Water Level Variation: 70 mm (2.8 in) up to 2000 mm (78.7 in) as standard. Up to 3500 mm or 5000 mm on request.

Water Lateral Velocity: ~30 cm/sec (~11.8 in/sec) without a stiller; May be doubled with a stiller or integral floating cage stilling plates.

Water Temperature: 0 – 70 °C (32 – 158 °F); no freezing

Air Temperature: -10 – 80 °C (14 – 176 °F)

Materials: Hydrocarbon resistant polymers (Polypropylene, PVC, Polyurethane), 316 stainless steel.

Diameter: 160 mm (6.3 in).

Integral Cable: 10 m (~33 ft.) supplied with sensor, 3 x 18 AWG, blue PVC jacket.

Guiding Cage Dia.: 560 mm (22.1 in).

Integral stiller plates for the floating guiding cage

ID-223 Sensor : ATEX Intrinsically Safe: II1G Ex ia IIC T4 Ga -40 °C to +70 °C. Also: IECEx, UKEX and cETLus

PS-220 Enclosure For hazardous areas:

Combined System: Approved for operation in hazardous locations when Zener Safety Barriers are added

Performance: EPA – Conforms to Spill Prevention, Control and Countermeasure (SPCC) – Oil Pollution Prevention regulation (40 CFR part 112), and EPA/530/UST-90/009 – Leak Detection Methods

Manufacturing: ISO 9001:2015 Certified

PS-220 Description: PS-220 Controller is an analog signal processor and power supply in a NEMA 4 enclosure that supports a single ID-223 sensor.

Temperature: Ambient temperature range: -40 – 85 °C (-40 – 185 °F)

Cable length to Sensor Up to 1,200 m (3,937 ft.) subject to hazardous area restrictions and cable type.

PS-220/RL/LI: Two alarm relays with dry contacts and one fail relay contact: SPDT rated 4A (3A for fail contact) at 250 VAC or 30 VDC, normally open and normally closed, and four status indication lights: Water, Oil, Air/High Oil and Fail. Includes built-in diagnostics.

Wiring Connections: Terminal blocks: 14 AWG maximum for sensor and 4-20 mA output wires; 12 AWG maximum for power and relays wires.

Enclosure Options:

Input Power Options: 220 or 110 VAC (50 – 60 Hz) or 9 – 36 VDC (@ 5 Watts); may also be solar powered.

/420: 4-20 mA analog output proportional to hydrocarbon thickness up to 25 mm (1.0 in), current source, not isolated.

/420/BG: Bar-Graph display (20 bars) of hydrocarbon thickness in addition to 4-20 mA analog output.

/CEN: Zener Safety Barriers to allow installation of the sensor in hazardous areas.

/AUD: Audio alarm option (available in weather-proof or explosion-proof enclosure)

SLC-220: Digital Signal Processor for up to four ID-220 Series sensors support, with various output options, including relays, lights, 4-20 mA, LCD, Modbus communication in RS-232 and RS-485, and remote cellular connectivity.